Categories

-

MARINE LOCKS

- 25 and 50 mm backset. Narrow Stile Stainless Steel Mortise Locks for Full Size Doors

- 25, 30 and 38 mm backset; Marine Grade Mortise Locks for Small Doors

- 40 and 50 mm backset. Marine Grade Mortise Locks GSV and S&B

- 55 mm Backset GSV Schwepper and S&B Marine Locks

- 55 mm backset Trioving Vingcard Marine Grade Mortise Locks

- 65 backset mm Marine Grade Mortise Locks for full Size Doors

- Italian Marine Locks - OIcese Ricci

- Italian Marine Locks -Razeto and Casareto

- Jado and Wilka Mortise Locks

- Pocket Door Sliding Mortise Locks

- Refrigerator Latches

- Sliding Door Mortise Locks

- MARINE LEVERS, ESCUTCHEONS & ROSES

- KEYING SYSTEMS - SCHWEPPER AND TRIOVING LOCKS

- CABINET HARDWARE, LOCKERS AND DECK BOXES

- MARINE GRADE HINGES

-

HATCH AND DECK HARDWARE

- Barrel Bolt / Transom Door / Bulwark Door Bolts. Stainless Steel

- Compression Latch Hatch Fastener Stainless Steel

- Deck Tie Downs 316 Stainless Steel Surface Mount

- Dogging Devices for Doors And Hatches

- Hatch Fasteners with Cam Operated by Triangular key

- Hatch fasteners with Cam operated by Winch Handle

- Hatch Lift

- Hatch lifts with Cam Hand Operated

- GLASS DOOR AND SHOWER DOOR HARDWARE

- SLIDING DOOR TRACK 316 STAINLESS STEEL

- CLEATS, BOLLARDS & HAWSE PIPES

-

DOOR HOLDERS, DOOR STOPS, WINDOW STAYS & DOOR STAY

- Ajar Hooks

- Door Holder Clamping Model

- Door Holder Hook Model

- Door Stay Stainless Steel

- Door Stays Brass

- Flush Bolts

- Magnetic Door Holder Heavy Duty

- Magnetic Door Holder Light Duty

- Magnetic Light Door Holder Plastic Ivory & Brown

- Push Door Holder

- Window Stay Brass

- Window Stay Stainless Steel

- Window Stay Telescopic Stainless Steel

- DOOR CLOSERS HYDRAULIC

-

GASSPRINGS / GAS STRUTS

- 06 Series Stainless Steel Gas Springs

- 08 Series Stainless Steel Gas Spring

- 10 Series Stainless Steel Gas Spring

- 10 Series Stainless Steel Gas Springs with Protection Tube

- 14 Series Stainless Steel Gas Spring

- 22 Series Stainless Steel Gas Spring

- 3 Special Gas Springs

- Gas Spring - End Fittings Stainless Steel

- Gas spring - Mounting Hardware

- Gas Spring Charging Kit

- Gas Springs Bleeding Kit

- FIRE FIGHTING AND HOSE DOWN EQUIPMENT

- PULLS / GRABRAILS / HOOKS / BRACKETS

- DECORATIVE DESIGNS FOR LEVERS, ESCUTCHEONS. ROSES

- TUBULAR LOCK SYSTEMS

- FLUSH BOLTS, EDGE BOLTS

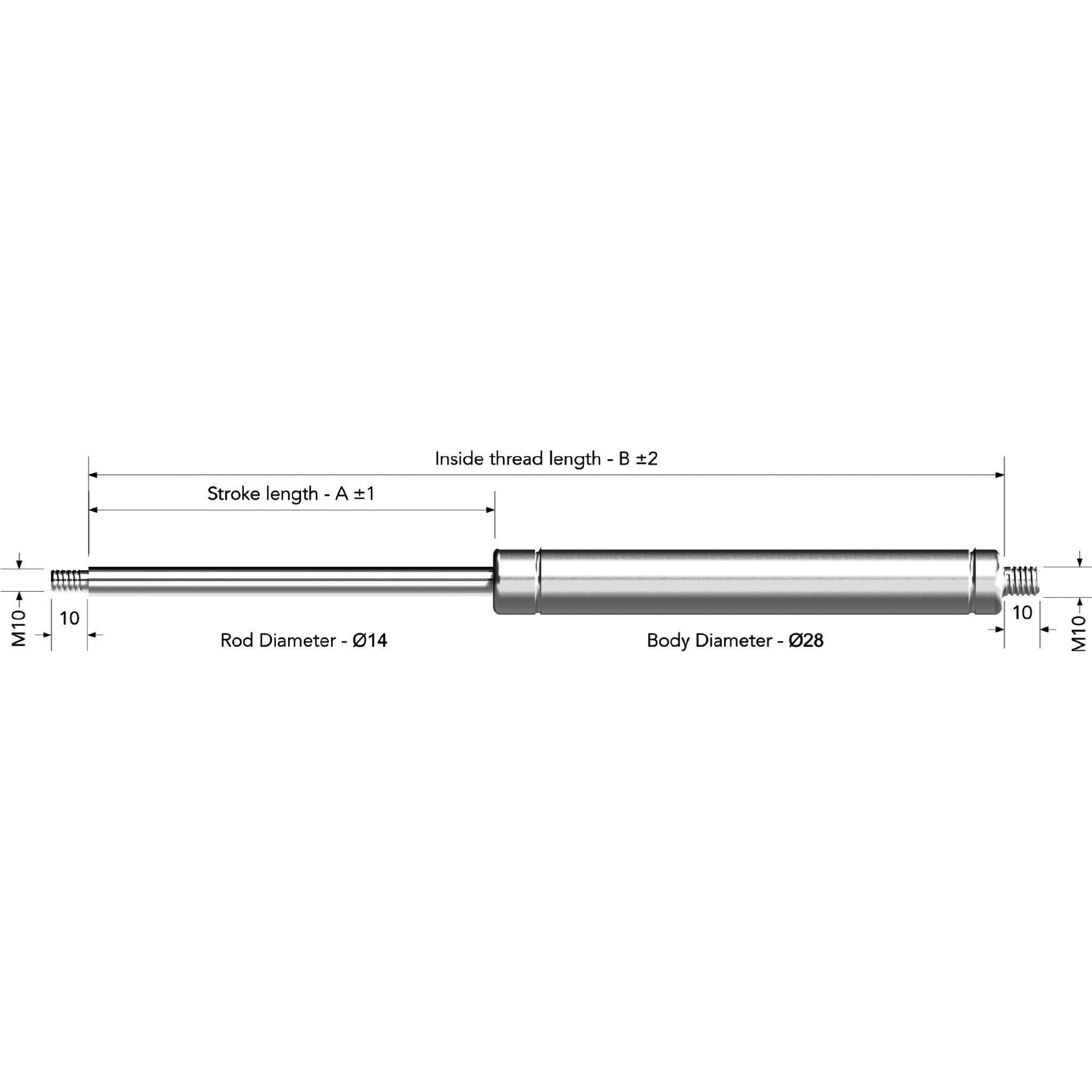

Gas Spring Series 14-28-250 mm. Each. Specify Newton Force Below

- Part#: 61.425

Specification

|

#61.425 |

14-28 |

“A” |

“B” |

62.123L |

62.127 |

62.135 |

62.140 |

|

|

Part ID |

Series 14-28-stainless steel gas spring with valve |

Stroke Length in mm |

Total length without attachments (not counting the thread) 2 x stroke+ 50 mm) |

Short Eyes, add 2 x 23 mm |

Long Eyes, add 2 x 27 mm |

Ball Joints, add 2 x 35 mm |

Forks Add 2 x 40 mm |

Thread size and max. N force per rod length* |

|

14-28-250 |

Extended |

250 mm |

550 mm |

596 mm |

604 mm |

620 mm |

630 mm |

M10x1.5 – 2500N |

|

|

Compressed |

250 mm |

300 mm |

346 mm |

354 mm |

370 mm |

380 mm |

M10x1.5 – 2500N |

|

CHARGING TABLE CONVERTING FROM NEWTON TO PSI, BAR, KG AND LBS.

*Psi and Bar relates to the pressure inside the gas spring cylinder for this series. *Kg and Lbs relates to the weight balanced by a specific Newton for this series *Force For each application add 10% force to compensate for friction etc.

FORCE CALCULATION FOR HATCHES AS FOLLOWS: Use full scale drawings and engineering calculations to find the correct gas spring size and force for your application. GENERAL INFORMATION: Install the gas spring as far away as possible from the hinge within the range of the stroke. Please note: Torque on the hinges will be at least be twice the force of the weight of the hatch. Use incremental lesser force for gas springs when hatch is lighter. Concidder our charging Kit #63.110 for professional users to charge your own gas spring. Considder our Bleeding Kit #63.001 to bleed down the pressure in your gas spring. We are providing general suggestions to complement your calculations. By purchasing our products you agree that we are not in any way liable or responsible for your actual installations of our products and its effects.

Stainless Steel Stock Range.

|